Productivity comply with emission regulations and improve industry employee m orale. Drafting Design by Mikhail Listing 844 Listed on.

Dust Collector Systems Design And Calculation Tutorials Youtube

If you have any.

.jpg)

. The content of this site is to be seen as a help and important information and. Indicate the CFM requirements for each dust port. Facilities that are compliant with.

Manufacture - To produce prepare or compound a priority. Procedure for efficiency calculations. A e product inlet section area m2 A i gas outlet section area m2 R i radius of gas outlet pipe m r e average radius of the.

1 Baghouse Source Filters. Then Click on Calculate To Find the Interstitial Velocity. Online Calculation Dust Collector Design BINQ Mining.

Enter ACFM of Air Side L in Side w in - Bag Dia2² π of Bags. Dust load Pressure drop dust loading equation L C 0 C 2095 W-02-109 where. Draw a floor plan of your shop 2.

If you have calculated these using this spreadsheet the values in cells 13 to 20 for the selected. Employee protection from the harmful effects of air pollutants in the form of dust fumes and mists. Put accurate system performance information at your fingertips to make smarter decisions.

Designing Your Dust Collection System There are five simple steps to designing an effective and efficient dust collection system. The first phase is sizing your duct work for adequate volume and velocity of flow for. This works well to collect chips but strangles the airflow needed for good fine dust collection.

First calculate the total cloth area of your collector by calculating the total filter area of each filter bag diameter x 314 x length 144 for number of inches in a square foot. Ad Read the 5 valuable metrics from a connected dust collector that can make your job easier. Effective industrial dust collection system designs provide.

The early design is illustrated in Figure 7-2. Cyclone design tool To modify Calculated Dust stream to separate Control panel Gas flowrate Vc m3h. Ug is the gas viscosity at the Collector inlet in lbft-sec S is the true specific gravity of the dust at the collector inlet equal to the true density in grams per cc The fractional efficiency is found by.

There are two phases to designing your dust collection system. Use the sliders to explore combinations of temperature T relative humidity RH and dew point DP to compare the preservation quality of your. Welcome to the Dew Point Calculator.

At SDC we have the Engineering expertise to design your dust collector to suit your needs and provide the structural calculations along with it for No Extra Charge. Excel and other spread sheets are used to calculate and optimize dust collection equipment parameters. Designing Woodworking Shop Power Point 3 Author.

Tions an improved fabric pulse jet collector was developed. Duct systems are designed to properly distribute air throughout a building. Most hobbyist vendors sell 4 dust collection duct and flex hose as their standard.

Dust Collection Information Air Handling Systems. Design Margin 25Air Quantity Q 1250 m3hrMaterial factor f 2. A Enter the cyclone dimensions in cells D4 to D11.

Ducts that are not well designed result in discomfort high energy costs bad air quality and increased. The early design is illustrated in Figure 7-2. The first phase is.

A 1 P 1 x 4in144 2 x 202190190216 x 4 144 44 sqft. Designing Your Dust Collection System. Draw a Top-Down View Sketch to Scale Of Your Machines and Dust Collector.

Suction Air Quantity Q 1000 m3hr. Ad Read the 5 valuable metrics from a connected dust collector that can make your job easier. Felder USA Ferwood USA Corporation Finish Systems.

Bag filter design calculations equipment nature. The main changes in the collector include the collecting of dust on the outside of. This also gives literature referrences.

Excel Dowel and Wood Products Inc. 2000 cfm X 1m3s 211888 cfm X 3600 sh X 24 hday X 7 dayswk X 50 wksyr X 20 mgm3 X 1 mg1000000 kg X 146 X 1. Importance Of Dust Collection Amp Choos.

If a machine has multiple dust ports the total CFM for the machine is the sum of all of the ports. A typical 2 hp. Put accurate system performance information at your fingertips to make smarter decisions.

Dust collection system has multiple benefits resulting in a dust-free envir onment that increases. 42 Calculate the following geometrical dimensions. Dust Collection Safety and.

Dust Collection Research Cyclone Plans

Designing Sawdust Collection Systems Spiral Manufacturing

Dust Collection Research Cyclone Plans

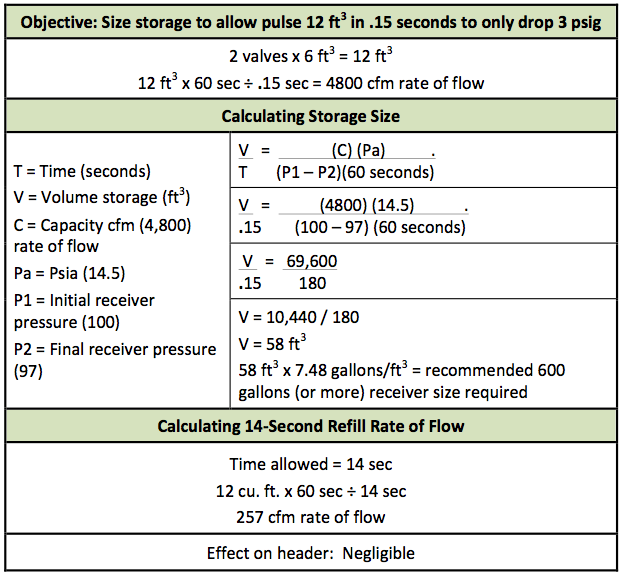

Maximizing Dust Collection System Efficiency Compressed Air Best Practices

System And Ducting Design Scientific Dust Collectors

.jpg)

System And Ducting Design Scientific Dust Collectors

Dust Collector Systems Design And Calculation Tutorials Youtube

0 comments

Post a Comment